ACTii AC7391 heating controller for Solar Panels

See the end of this post for the new updated Model: ACTii AC7392 that runs 100% off solar.

REFERENCE: https://actii.pl/en/ladowarki-prostowniki/979-mpm-pwm-heater-charging-controller-for-solar-solar-panels-actii-ac7391-6931240073919.html

Original Model: ACTii AC7391 Price and Availability.

PWM regulator for heaters with the algorithm for searching the maximum MPPT power point from solar panels.

The solar water heater controller enables the supply of standard DHW electric boilers from solar panels.

The solar panel operates at maximum power only at the optimal voltage. Connecting the heater directly to the photovoltaic panel causes too heavy load and as a result voltage drop. At reduced operating voltage, the panel produces even several times less current than at optimal voltage. The use of a charge regulator eliminates this problem. Even on cloudy days it will be possible to heat the water in the boiler.

A buffer module containing capacitors, a choke, diodes is added to the regulator, which allows greater efficiency (up to 30%) and reduction of interference caused by PWM regulation.

The solar water heater controller is equipped with a temperature sensor – which MUST be fitted for operation, which allows the boiler to stop heating above the set temperature.

The device is equipped with an additional relay output (without potential) enabling notification of external devices that water heating has been completed (reaching the set temperature) or that the device has failed. This output allows you to connect additional devices.

Tolnix Report

Product: MPPT PWM DC Solar Hot Water

Brief: My 400lt stainless steel tank with thermal solar needed a boost.

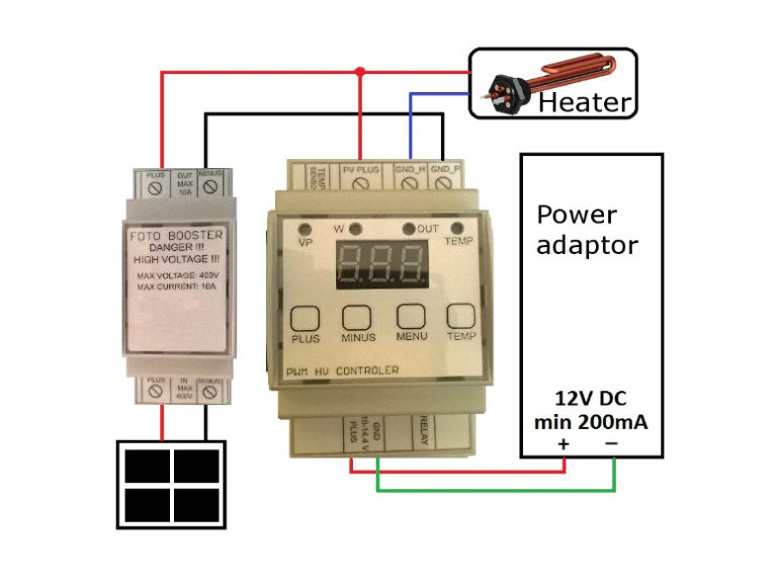

While this company has done a good job translating their user manual – we thought just a few fixes may help readers. Firstly, this system can use up to 2kw of solar, basically through any electric resistance element of 2kw or higher. Simply connect as shown. It requires an external power source to operate.

It’s default MPPT value is 100 volts (on display once connected) and requires the temperature probe to be connected to operate. The unit can be mounted on standard DIN switchboard rails BUT MUST have ventilation holes as the unit contains it’s own cooling fan.

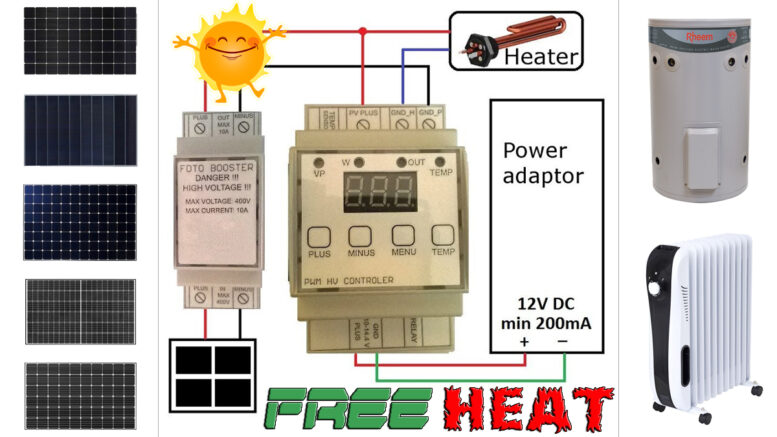

This unit is great for electric water heating elements and electric oil heaters to provide FREE heating while the sun shines! Good after sales service – but you do pay for a quality product.

The only downsides – the rather high MPPT voltage level and the need for external power.

The upsides – it works with different resistance heating elements so no need to change them to work with the sun!

DISCLOSURE: I have no association with this company – I have purchased 3 of these units. Two run oil heaters, one runs a lower hot water tank element and one powers a 1kw concrete slab heater around our pool to take the chill off the tiles.

MPM PWM Heater Charging Controller for Solar Solar Panels

Model: ACTii AC7391

EAN: 6931240073919

SKU: 739155867

-

PWM solar water heater regulator for heaters with the algorithm for searching the maximum MPPT power point from solar panels. The controller enables the supply of standard DHW electric boilers from solar panels

-

The controller is equipped with a temperature sensor, which allows the boiler to stop heating above the set temperature. It is possible to change the set temperature

-

The controller displays: Voltage (V), Power (W) transferred to the heater, Water temperature in the boiler

-

The controller can be turned off and on (plus and minus buttons)

-

The OUT diode blinking indicates current transfer to the heater

-

Relay output informing about heater interruption. They can be used to connect external devices

-

The device is mounted on a DIN TH35 rail

-

The controller has thermal protection and active cooling depending on the temperature of the actuator and power

-

For safety reasons, the high-voltage part is galvanically separated from the power supply

-

Two operating modes: Automatic mode, Mode with the option of setting the voltage activation thresholds

-

Possibility of connecting a wind turbine instead of a solar panel

Made in EU

Description

PWM regulator for heaters with the algorithm for searching the maximum MPPT power point from solar panels.

The controller enables the supply of standard DHW electric boilers from solar panels.

The solar panel operates at maximum power only at the optimal voltage. Connecting the heater directly to the photovoltaic panel causes too heavy load and as a result voltage drop. At reduced operating voltage, the panel produces even several times less current than at optimal voltage.

The use of a charge regulator eliminates this problem. Even on cloudy days it will be possible to heat the water in the boiler.

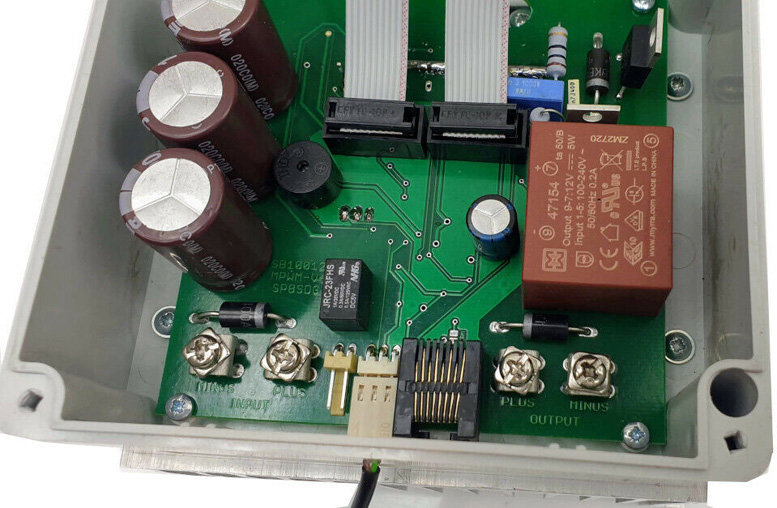

A buffer module containing capacitors, a choke, diodes is added to the regulator, which allows greater efficiency (up to 30%) and reduction of interference caused by PWM regulation.

The controller is equipped with a temperature sensor, which allows the boiler to stop heating above the set temperature.

The device is equipped with an additional relay output (without potential) enabling notification of external devices that water heating has been completed (reaching the set temperature) or that the device has failed. This output allows you to connect additional devices.

ACTii AC7391 Solar Water Heater Specification

Parameters

-

Supply voltage: 11V to 14.4V

-

Panel voltage: 10V to 400V DC

-

Panel current: MAX 10A

-

Maximum heater power: 2kW

-

Maximum power of panels: 2kW

-

Current drawn from the power supply without cooling: 0.08A

-

Current drawn from the power supply with cooling: 0.23A

-

Accuracy of temperature measurement 0.1 degrees

Modes of operation

The regulator has the ability to change the mode to work in the area between the min and max voltage, as it was in earlier versions. This option is especially useful for wind farms.

MODE ONE

It is fully automatic and starts working immediately after connecting.

When the voltage on input exceeds the minimum voltage threshold set with the MINUS button.

If the voltage during tuning falls below this value, the search remains interrupted.

Setting the minimum value allows free heating water and also the ability to charge batteries.

MODE TWO

Switching voltage thresholds can be set (from which it starts to increase PWM value) and maximum voltage (from which the duty cycle is filled) is 100%), i.e. all the energy of the cells goes directly to the heater.

Additionally, the use of this method allows panels to be kept at MPPT (the largest power point), and is especially useful for power stations wind.

In this case, it does not allow excessive acceleration turbine as well as allows its free start.

Dimensions

Controller dimensions: 90 x 54 x 64 mm (D x W x H)

Buffer dimensions: 90 x 36 x 64 mm (D x W x H)

Length of temperature sensor cable: about 100cm

Certificates and standards

CE, RoHS

Kit Contents

Regulator

Buffer

Package

Instruction

Temperature sensor

Warranty

12 months

Dimensions, Weight

Product dimensions: 90 x 54 x 64 mm (D x W x H)

Packaging dimensions: 100 x 120 x 60 mm (D x W x H)

Product weight: 330 g

Weight with packaging: 376g

SOLAR WATER HEATER USER MANUAL

USER MANUAL – PWM REGULATOR HEATER FIRED WITH SOLAR PANELS

Actii AC73911

1. NOTES ON SAFETY

-

-Before commissioning read this manual.

-

-All connections and changes must be made while the power supply and the voltage of the panels.

-

-Is necessary to ensure proper working conditions, in accordance with the specifications of devices, such as supply voltage, temperature, maximum current consumption.

-

-Installation and setting up devices need to have appropriate skills, so they can only be performed by qualified personnel, after reading the whole manual.

-

-Incorrectly connected equipment may be damaged.

-

-Responsibility for proper installation responsibility of the person assembling. Make sure you have met all guidelines and standards in the country.

-

-Electrostatic discharge can damage the unit. Use proper protection.

-

-It should protect the system against lightning by removing the controller from the panel during a storm.

-

-Any unauthorized alteration, modification and repair attempts will void the warranty.

-

-The regulator must be disconnected from the panels leave the apartment for more than one day !!!

2. TECHNICAL DESCRIPTION AND PRODUCT PROPERTIES

Heater controller is used to control the load panels by changing the filling factor of the PWM, and the combined buffer charge as the active load, which enables the panels at the point of MPPT, the highest power factor. For proper operation and yields the greatest power to provide an adequate load for the controller.

The regulator should be charged with a heater adapted to strong nominal power panels, and a voltage corresponding to the voltage MPPT panels. Generally, the idea is that the regulator was an element of reducing the load of panels in case of no sufficient sunlight, and thus allowed the maintenance of the panels at the optimum operating point.

The controller itself is nothing but a very fast relay SSR, which should be equipped with a module with capacitors, so that the panels will be properly loaded.Without the buffer charge controller works as a normal thermostat, which charged up at the moment of inclusion or completely relieves the time off.

The presence of the cache increases system performance by approx. 30%. The controller also acts as a thermostat preventing overheating of the boiler. Controller for its correct operation requires a stabilized power supply voltage specified in the parameters of the device.

The controller has a number of safety features such as active cooling (incorporated in the case at 37 degrees or above power 1900W) excluding below a temperature drop of 35 degrees or below 1500W power. This solution provided a comfortable environment for operating the actuators (transistors) providing sufficiently high security.

In case no sufficient cooling (e.g. in the case of staining the heat sink, fan failure) was used as an additional security emergency shutdown at a temperature of 60 degrees, which is to protect the output stage from being damaged by heat.

The device also monitors the supply voltage, and when it is too low (not enough to make the transistors in saturation mode) activates the function disable transistors.This prevents conduction in the active mode, and thus exposed to excessive amounts of heat separation, which could damage the actuators.

The device is equipped with an additional relay output (potential-free) to enable external notification devices that heat water has been completed (achieving the set temperature) or entry into Safe Mode (failure actuator) ER.1.

As an additional security elements applied with a SSR DC, which makes it possible emergency stop heating the water in the event of an actuator. This solution gives almost full security assurance solar power.

3. ACCOMMODATIONS AND CONNECTION

The device to work properly requires a proper connection. The target location to mount the box is equipped with surface-mounted rails TH35 and additional ventilation holes. The lack of holes can lead to too frequent entering control mode emergency shut down due to excessive heat.

WARNING!!!

The presence of buffer loads is not necessary for operation, however, significantly increases the efficiency of the system providing the maximum energy output of panels.

WARNING!!!

Buffer charge the capacitor battery can be replaced, but the solution will be quite safe and aesthetic.The recommended connection arrangement control is given below. It does not present the possibility of using additional output RELAY serving example.

Disconnecting the panels (by SSR DC) in the event of failure of the controller.

The regulator should be connected as shown below.

4. Configuration

Configuration is to set the minimum operating voltage (required for proper operation of the battery charge controller (if any)) operating mode and the temperature set point of the boiler. Changing the operating mode: This is done by holding the MENU button until you change the subtitle display.

There are two modes

MODE ONE: It is fully automatic and starts to work immediately after connecting. When the voltage at the input exceeds the minimum voltage threshold settable by pressing MINUS. If the tuning voltage falls below this value, the search is interrupted. Setting the minimum value gives you free water and heating at the same time the possibility of charging.

MODE TWO: The ability to set threshold voltage switching (from which begin to increase the value of the PWM) and the maximum voltage (from which the duty ratio is 100%), ie all the energy cells goes directly to the heater.

Additionally, this method allows to maintain the panels at a point MPPT (greatest point of force), and is particularly suited for wind turbines. In this case it prevents excessive ramping of turbines as well as it allows free start.

Setting the minimum operating voltage (only MODE 1) is done by holding the MINUS(when I set the operation mode) to change the state of the display. Then we adjust the minimum operating voltage, which is stored after a few seconds of inactivity.Setting the set temperature of the boiler is carried out analogously, or by holding the TEMP to the change of the display.

Then we can set the desired temperature with an accuracy of 1st. After a few seconds of inactivity the device saves the setting and switches to normal operating mode.

NOTE!!!

Changed settings are stored in non-volatile memory and are still active after a reboot.

During normal operation, the display shows the following parameters, the LED lights PV is the current voltage is displayed on the panels, the LED lights in the display shows the current power delivered to the heater.

When the light is flashing OUT it indicates that the heater is in the active control. Steady suggests that the heater is fully actuated (filling 100%). No light suggests the heater off. TEMP suggests diode display of the actual temperature of the boiler temperature to the nearest 0.1 degree.

FACTORY DEFAULT SETTINGS

To restore factory settings, hold the MENU button when you turn the device.

Using this function will be deleted all user settings.

5. TECHNICAL DATA

| Power supply for display and function | 11 V to 14.4 V |

| Solar power combined voltage maximum rating – open circuit | From 10V to 400V DC |

| Solar power current maximum rating | 10A |

| Maximum heater power – larger element power ratings is fine | 2kW |

| Maximum solar panel power | 2kW |

| The current drawn from the power supply without cooling fan running | 0.08 A |

| The current drawn from the power supply with the cooling fan running | 0.23 |

| The accuracy of temperature measurement | 0.1 Degree |

6. INFORMATION SERVICE

WARNING!!!

DISPLAY MESSAGE: ER.0 Indicates an emergency shutdown of the driver due to low supply voltage, which could lead to damage to the heater control transistor.

WARNING!!!

DISPLAY MESSAGE: ER.1 means damage control transistor, immediately disconnect the controller and return to the site. At the time of display of this error is still powered heater panels and the controller is not able to turn it off!Leaving the regulator of this error can lead to melting, and even fire.

POSITIVES

-

The solar energy is “free” energy

-

Accepts a wide range of standard rating elements

-

Very professional build

-

Simple installation

-

Compact size

NEGATIVES

-

Cooling fans can be noisy and must have no restrictions

-

Relies on power to operate

-

Power generated is free, power to run this is not

-

Not an “off grid” solution

-

Requires special mounting

EXAMPLE: Out power went out recently. I thought “great, this will be heating our pre-heat storage tank” but as it requires electricity to run, so we had cold showers.

The CE symbol on the device means the device’s conformity with EMC Directive 2004/108 / EC (Electromagnetic Compatibility Directive). This sign on the controller states it “is forbidden to place the used equipment together with other waste.” Equipment must be delivered to the designated points of dealing with disposal. (According to the Act on waste electronic equipment dated 29 July 2005)

Business seller information

FUH Actis Ewelina Golab

Ewelina Golab

Andersa

6D/13

66-400 Gorzow Wlkp, lubuskie

Polska

Phone:095 7881970

Fax:0957881970

Email:shop2@actii.pl

Search eBay or visit: https://actii.pl/en/

NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024 NEW 2024

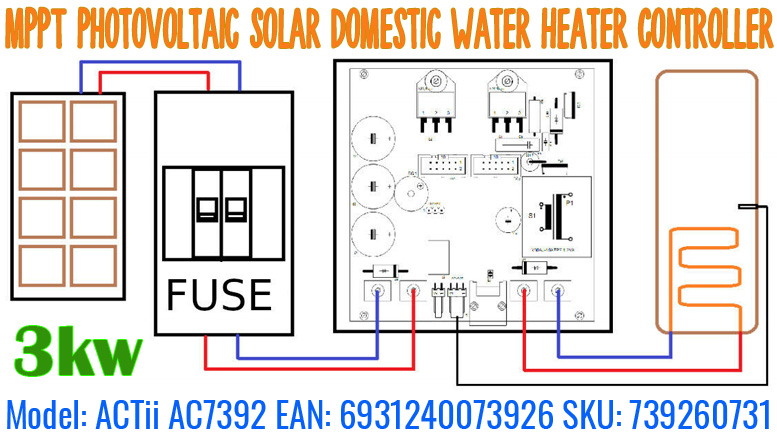

3KW PWM MPPT Heater Boiler Charging Controller Solar Photovoltaic Panel PV Hot Water

PWM MPPT 3KW Heater Charging Controller for Solar Photovoltaic Panels

Model: ACTii AC7392

EAN: 6931240073926

SKU: 739260731

PWM controller for heaters with the algorithm of searching for the maximum MPPT power point from photovoltaic panels. The controller enables the supply of standard DHW electric boilers from solar panels.

- The controller is equipped with a temperature sensor, which allows you to stop heating the boiler above the set temperature. It is possible to change the set temperature. Two displays – one displays the current DHW temperature, the other shows the current power by default or, after switching, the voltage from the panels and the peak power.

- Built-in payload buffer. It enables higher efficiency (up to 30%) and reduction of disturbances caused by PWM regulation. Transistors with a large margin (ensure long, trouble-free operation)

- The regulator is powered by PV panels. There is no need to connect an external power supply. (RJ45 socket can also be used to power the controller when there is no voltage from the panels)

- Large heat sink for passive cooling, eliminating the need for a driver fan.

- The controller has thermal protection and active cooling depending on the temperature of the actuator and power.

- RS485 communication port for reading operating parameters from a computer.

- Temperature control of the heat sink and the inside of the housing. Built-in acoustic alarm.

- The regulator can be turned off and on (plus and minus buttons).

- Relay output informing about the heater heating interruption. They can be used to connect external devices.

- Made in the EU.

Description

PWM controller for heaters with the algorithm of searching for the maximum MPPT power point from photovoltaic panels.

The controller enables the supply of standard DHW electric boilers from solar panels.

The solar panel works at maximum power only at optimal voltage. Connecting the heater directly to the photovoltaic panel causes too high a load on it and, as a result, a voltage drop. At reduced operating voltage, the panel produces even several times less current than at optimal voltage. The use of a charge regulator eliminates this problem. Even on cloudy days, it will be possible to heat the water in the boiler.

Built-in charge buffer, which enables higher efficiency (up to 30%) and reduction of disturbances caused by PWM regulation.

The controller is equipped with a temperature sensor, which allows you to stop heating the boiler above the set temperature.

The device has been equipped with an additional relay output (potential-free), which allows external devices to be notified that water heating has been completed (the set temperature has been reached) or that there has been a device failure. This output allows you to connect additional devices.

Specification

Parameters

Supply voltage: power supply to the controller from PV panels

Panels voltage: From 10V to 350V DC

Panels current: MAX 13A

Maximum heater power: 3kW

Maximum power of panels: 3kW

Current consumption: 0.08 A

Temperature measurement accuracy: 0.1 degrees

Mode of action

Configuration consists in setting the preset temperature to be achieved by utility water. This is done by pressing the MENU button until is displayed intermittent sound from the driver. Then, the inscription “S.tE” appears on the upper display, which means setting the preset temperature. It is possible to reduce the voltage starting the operation by the regulator, but this option is recommended when an external power source is used. The starting voltage can be reduced by holding down the minus button until an intermittent signal from the buzzer appears. The default start voltage is 150V.

Switching the regulator on and off: The regulator can be turned off by briefly pressing the MINUS button (voltage is no longer supplied to the heater).

Switching on is done by briefly pressing the PLUS button. By default, after turning on the power, the regulator automatically starts to work (supplying current to the heater using the algorithm of searching for the maximum power point MPPT.) If the voltage exceeds the minimum value. The regulator can work only with photovoltaic installations, it cannot be used with wind turbines. The regulator, apart from the settings described above, does not require additional maintenance. Adjustment of operating parameters is automatic and depends on the capabilities of the panels and the load. The regulator must be loaded ONLY with heaters used in boilers. Air resistance heaters or other electronic devices must not be used.

Additional information

Temperature sensor cable length: approx. 100 cm

What heater should I use AC or DC and what power?

As the resistance is the only parameter that describes the heater, you can use an AC or DC heater.

The heater should be matched to the photovoltaic panels.

If your PV panels are rated at 140V DC 7.14A 1000W, a 140V DC heater with 1000W will be the most appropriate, but you can also use a 230V AC or 110V AC heater. You only need to adjust the heater’s power to the PV panels. (we provide an online calculator to calculate the correct heater).

Accordingly, (because the heater’s resistance and current intensity are the only parameters of the heater), it is possible to adjust the 230V heater to work with PV panels with a different voltage, using Ohm’s law. 140V / 7.14A = 19.61 Ohm. Our heater is to have 19.61 Ohm. For a 230V heater, P = U * U / RP = 230 * 230 / 19.61 = 2697W. We can therefore use a 230V AC heater with a power of approximately 2700W for PV panels of 140V 7.14A.

The heaters can have two independent coils. One spiral can be used to heat water from PV panels and the other from 230V mains.

During normal operation, the display shows the following parameters, the current power and the DHW temperature. Blinking OUT diode signals that power is being supplied to the heater.

The device has been equipped with an additional relay output (potential-free), which allows external devices to be notified that water heating has been completed (the set temperature has been reached) or the emergency mode has been entered (failure of the actuator).

Kit contents

Regulator with load buffer

Package

Instruction

Temperature sensor

Cable connectors

Certificates and standards

CE, RoHS

Dimensions, Weight

Product dimensions: 130 x 140 x 120 mm (D x W x H)

Packaging dimensions: 140 x 150 x 140 mm (D x W x H)

Product weight: 1130 g

Weight with packaging: 1200 g

Business seller information

Przedsiebiorstwo Action Jan Golab

Jan Golab

Andersa

6D/13

66400 Gorzow Wielkopolski, lubuskie

Poland

Phone: 570908556

Email: shop2@actii.pl

Value Added Tax number: DE 327183481PL 5992602962

The seller provides invoices with VAT separately displayed.

Independent forum discussion: https://diysolarforum.com/threads/actii-7392-mppt.50456/

Manufacturers website: https://actii.pl/en/ladowarki-prostowniki/1248-pwm-mppt-3kw-heater-charging-controller-for-solar-solar-panels-actii-ac7392-6931240073926.html

Instructions: English Instruction Manual

Hallo,

kann der Controller auch mit Monokristalinen PV Modulen 60×20 Zellen mit einem Kurzschlussstrom Isc 11,33A (STC) bzw. 9,15A (NOCT)betrieben werden? Welche Werte sind zu beachten?

MFG

EDITOR, TRANSLATION: Hi there,

can the controller also be operated with monocrystalline PV modules 60×20 cells with a short-circuit current Isc of 11.33A (STC) or 9.15A (NOCT)? Which values are to be considered?

Kind regards

Yes, there are many configurations that WILL work. I suggest you look at the website for further information: http://techluck.com/