Do you have to solder bare copper wires?

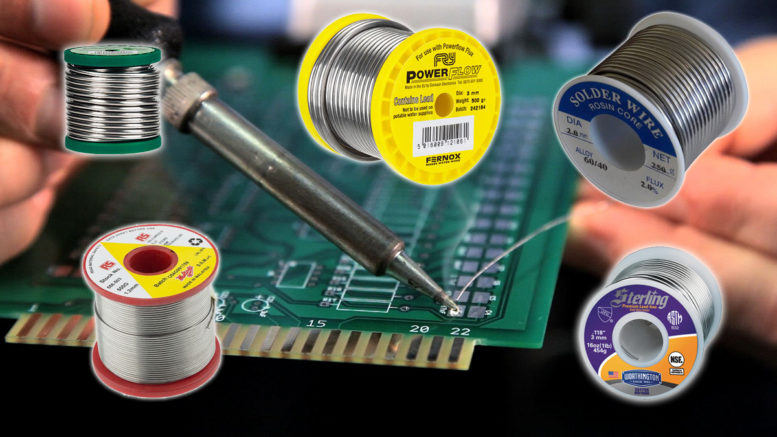

Commonly called “tinning”, solder has a great many uses in plumbing, electrical and light metal work. It comes in many types, so purchase accordingly – though I find the old “contains lead” solder to work the best.

I was fortunate to enjoy electronics as a school subject in my youth. Then followed into the Australian Defense Forces manufacturing industry as an Electrical Fitter often working on the army’s diesel generators and early Bofors Anti Aircraft guns at what was known as the Maribynong Ordnance Factory (no longer there – it’s now all housing!).

It was here we did huge amounts of soldering, cable dying – (yep, you heard right, even colored our own cables), wiring looms, AC motor repairs among many of the factories other maintenance necessities.

There are way to many reasons to argue, so today, we will just enjoy my opinion. Do I solder bare copper wires? And why?

It depends; usually, if its going to be outside – I will, if I’m using a crimp lug, I will back it up with some solder to make sure it doesn’t pull out. Unless I’m using commercial quality equipment and lugs, I tend to remove the cheap plastic cover, crimp it, solder it, heat shrink it.

I also like to let the resin core flux solder draw slightly back up inside the sheathing so there is no weak point where the insulation ends. I also tend to use heat shrink tubing for further strength and insulation.

A good quality soldering iron with “the right amount of heat” and a nice, clean, solid tip is a must. Luckily, soldering irons are fairly simple and very affordable from electronics stores or eBay. You can find most of the suitable types well under $50.

So, not much to learn here – just one of those things everyone tinkering with AC or DC should known. Some history, it “use to be” forbidden to solder the panel wiring on fighter aircraft in case of a short creates heat enough to melt the solder and drip in to other critical areas.

A side note; if you are intending to screw clamp your wiring like inside at the back of a light fixture – a soldered wire can be more difficult to squish with the screw causing less electrical contact than leaving it bare, again, it all depends!

You may find some of these articles – well, not overly exciting. But some of these “knowledge posts” can be useful and save a lot of grief.

FOOTNOTE

This will be covered elsewhere but; do I solder lithium batteries? We are talking in particular 18650 lithium ion batteries. I no longer do, but I have. “If” you wish to solder them, PLEASE watch one of the many YouTube tutorials as there are certain techniques that work better than other, and reduce the battery’s exposure to excessive heat!

Be the first to comment on "Why I Solder Copper Wires"